+86 - 158 7555 3143

Rogers 4790-79-09030-04P polyurethane foam is a foam material of the PORON 4790-79 ShockSeal™ series. It has many outstanding properties, flame retardant, abrasion resistant, heat resistant, cold resistant, cushioning, sound absorption, shockproofing, and sealing, such as excellent resistance to compression deformation, super high resilience, impact resistance, elasticity durability, etc. Is widely used in all kinds of precision products shockproof and other roles.

It can meet the requirements for fixing and sealing smooth parts of various components and is suitable for non-structural fixing and sealing of small and light-shaped materials with good waterproof performance.

It is suitable for vibration sealing of new energy vehicles, electronic equipment products, refrigerators, and air conditioning interiors. It is also suitable for external coating, processing, and related product customization and stamping. It can withstand high temperatures of 150℃ and low temperatures of minus 40℃. It also plays an irreplaceable role in the die-cutting of electronic parts.

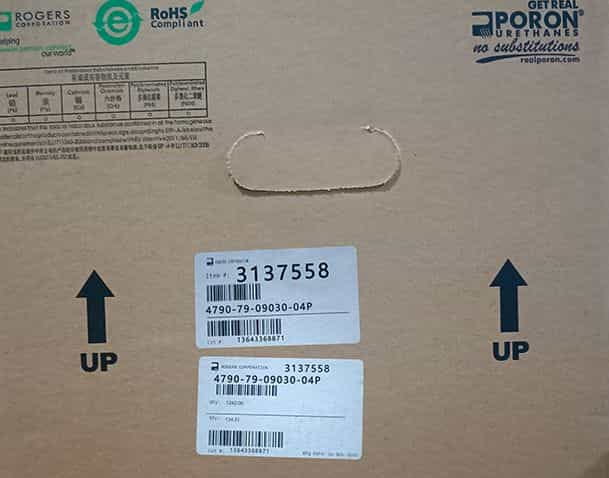

| Rogers Polyurethane Foam 4790-79-09030-04P | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPICAL ROLL SIZE | ||||||||||||

| DENSITY | THICKNESS | WIDTH | LENGTH | TOTAL | APPROX. WEIGHT | |||||||

| PRODUCT DESCRIPTION | lbs/ft3 | kg/m3 | inches | mm | inches | mm | feet | m | ft2 | m2 | lbs. | kg |

| 4790-79-09021-04 P | 9 | 144 | 0.021 | 0.53 | 40T | 1016 | 350 | 106.7 | 1166 | 108.4 | 45 | 20 |

Rogers 4790-79-09030-04P polyurethane foam is ideally suited for applications where flexibility is particularly important. The foam material maintains its integrity and effectiveness in gap-filling, gasketing, and vibration isolation applications.