+86 - 158 7555 3143

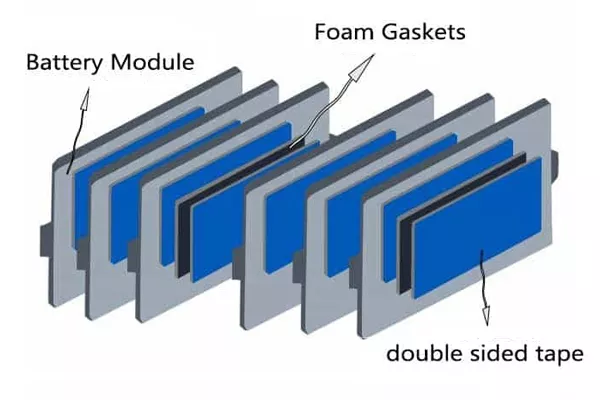

Polyurethane foam material in the new energy vehicle power battery plays a crucial role in the new energy vehicle power battery, which is related to the safety of the battery pack and the whole vehicle, the cooling system inside the battery pack has been changed from the traditional air cooling to liquid cooling, but the direct contact between the liquid cooling plate and the battery pack will cause the liquid cooling plate to be in a long-term weight-bearing state, plus its own alloy structure, which will produce a certain physical deformation, and the middle position will have a certain collapse, causing the contact interface with the battery pack to have a gap, which is not conducive to heat transfer. The contact interface with the battery pack will have a gap, which is not conducive to heat transfer, which requires corresponding support for the liquid-cooled plate structure to prevent the deformation of the liquid-cooled plate structure so that the battery pack can be connected without gaps to facilitate heat transfer.

According to the application environment, the performance requirements of customers for liquid-cooled plate support products are as follows:

In response to customer requirements, our polyurethane foam products are specially developed to meet customer needs for sealing support foam material, which has a stable and detailed foam structure, strong pore wall, as thin as 0.8mm can reach UL94V-0 fire retardant level, can work normally in the range of -50-200 ℃, low smoke and low toxic emissions, excellent resilience, after testing under severe temperature conditions, stress The relaxation loss is very small, which is very suitable for customer's products in this severe environment. After several prototypes and repeated tests, this material has been adopted and is now in mass use.