+86 - 158 7555 3143

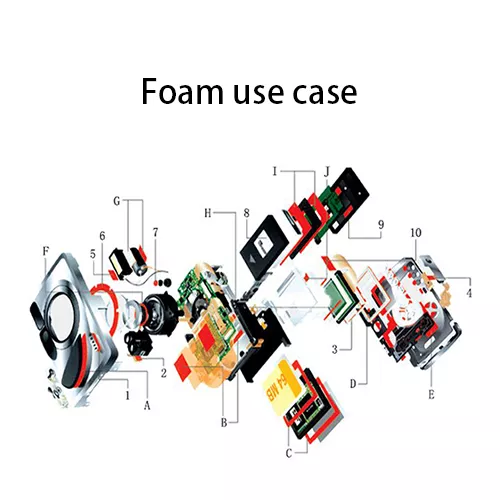

The compressibility and good thickness retention of Rogers' new polyurethane foam material, along with its excellent waterproof sealing effect. It can help with the anti-shock sealing of digital cameras.

In today's increasingly popular digital camera, the camera is a high-precision electronic optical instrument, and its internal components and lens position must be kept very precise, any misalignment and damage will make the camera unpredictable damage, not to mention the drop, or violent vibration may also cause damage to the camera.

As an electronic product, water is undoubtedly its biggest nightmare, not only the water will completely bury an electronic device, but moisture, mold, and mildew problems are also not optimistic. If your camera is not a three-proof model, shockproof, and waterproof are very important.

Rogers' new polyurethane foam material is compressible and has good thickness retention, but also has an excellent waterproof sealing effect. It can help the digital camera shockproof sealing.

In daily life, we should pay attention to avoiding digital cameras in use do not directly shoot the sun or bright light, not in the hot sun; card camera trial process is best to turn on the camera's "hibernation" function, in a period of time not to operate the camera lens automatically retracted to play a role in the protection of the lens; try to avoid not in the outdoors will be Camera lens from the body screwed down, to prevent the lens into the dust.

A.Fixing of rubber parts

B.PCB protection

C.Flash card

D.Fixing of LCD buffer pad

E.Fixing of buttons and hard material

F.Fixing of the mirror cover

G.Fixing of flash battery/buffer pad

H.Fixing of reflective die

I.Fixing of the battery board

J. Fixing of LCD module

1. Nameplate

2. FPCB

3. LCD module fixing

4. FPCB fixing

5. FPCB fixing

6. Battery board fixing

7. Serial number label

8. Earpiece/microphone dustproof pad

9. Lens cushion pad

10. FPCB fixing

Advantage:

Features:

Application areas:

Polyurethane foam is widely used for cushioning in cell phones and laptops, electronic devices, as well as in the interiors of aerospace and rail vehicles. Urethane foam has excellent resilience, good vibration and impact absorption, and an excellent waterproof sealing effect. Its wide range of hardness and thickness options and ease of compression makes it suitable for applications requiring high flexibility.

Applications Scope:

Cell phone speakers, power modules, lampshade sealing, automotive, electronic equipment, and computer communication equipment industries

Electronics, cameras, speakers, LCDs, signage, etc. fixed bonding and protection

Battery, plug compression foam

Computer, and electronic equipment, such as foot pads