+86 - 158 7555 3143

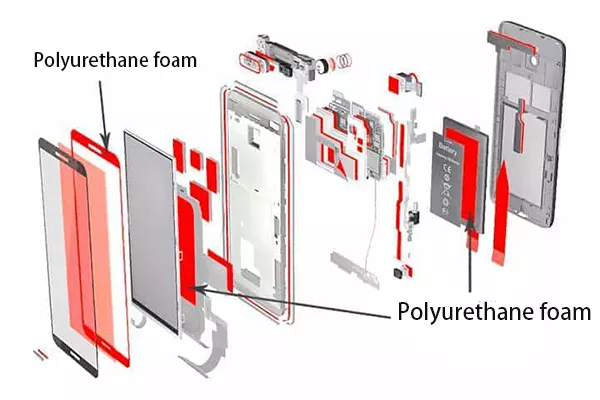

Polyurethane foam provides thin, light, and soft sealing and cushioning protection for smartphone displays. When designing display protection for portable devices, thinner and lighter profiles, variations in manufacturing tolerances, temperature fluctuations, water resistance and drop testing all add to the difficulty of electronic and electrical products. Polyurethane foam materials can be used for electronic devices to absorb and disperse impact energy, protecting the display and the electrical components inside from vibration, dust, moisture, and particulate matter.

Main Uses

Anti-vibration protection

In order to protect the display from shock vibration, the display or LCD gasket must absorb and disperse shock energy to prevent cracks or other damage caused by mechanical shock. Polyurethane foam material absorbs and disperses impact energy, helping to prevent unwanted cracks in the display. Polyurethane foam materials provide superior protection against mechanical shock and impact damage.

Display back padding

For touch screens on tablets and other devices, display back pads help achieve superior cushioned sealing and provide long-term reliability. Back liner applications require an extremely soft material that disperses forces, provides good resistance to compressive deformation and compressibility, has a low spring back, and has good resistance to stress relaxation.

Reinforced Displays

In outdoor or industrial touchscreen applications, LCD displays must be able to withstand vibration, physical shock, and temperature fluctuations, while providing a highly conformable seal and gap fill. Polyurethane foam materials achieve good vibration isolation and shock absorption performance under stringent conditions.