+86 - 158 7555 3143

Electronic devices are often prone to contact with sweat in daily use, and in the event of an accident will encounter tea. These situations are increasingly stringent requirements for the waterproof sealing of electronic devices. It has become a challenge for engineers to design and produce foam materials that are waterproof.

Rogers waterproof sealing foam series uses water-repellent raw materials added to polyurethane to produce polyurethane foam that meets the material's compressibility and good thickness retention properties while providing excellent waterproof sealing effects. It can help with the waterproofing problem of electronic equipment.

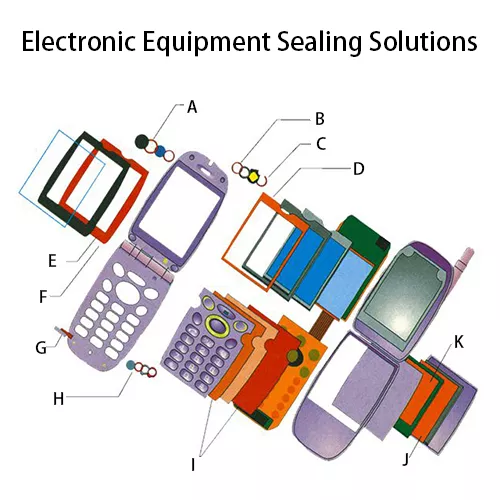

Application examples of sealing foam for electronic devices

A: Speaker paste

B: Speaker shock absorption is fixed

C: speaker dust proof material fixed

D: The monitor is fixed and pasted

E: window frame fixed paste

F: Paste of glass sheet

G: Name brand paste

H: Microphone gauze shockproof paste

I: fixation of the insulation film

J: The battery case is fixed with shockproof material

K: Battery is fixed and pasted

Advantage:

Features:

Application areas:

Polyurethane foam is widely used for cushioning in cell phones and laptops, electronic devices, as well as in the interiors of aerospace and rail vehicles. Urethane foam has excellent resilience, good vibration and impact absorption, and an excellent waterproof sealing effect. Its wide range of hardness and thickness options and ease of compression makes it suitable for applications requiring high flexibility.

Applications Scope:

Cell phone speakers, power modules, lampshade sealing, automotive, electronic equipment, and computer communication equipment industries

Electronics, cameras, speakers, LCDs, signage, etc. fixed bonding and protection

Battery, plug compression foam

Computer, and electronic equipment, such as foot pads