+86 - 158 7555 3143

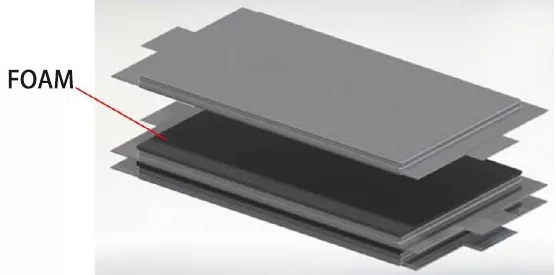

Foam in the power battery pack can provide excellent heat insulation, buffering, flame retardant, sealing, support, shock absorption, and other functions, so the foam can be used in different areas of the battery pack.

In the cell, when the cell occurs thermal expansion and cold contraction, foam can play the role of heat insulation buffer; When the cell is out of control, the foam can prevent heat transfer and has the flame-retardant property. In the battery pack, located under the liquid cooling plate or next to the upper and lower box cover, foam can play a support, shock absorption role; It can also be used as a battery sealing ring.

There are many types of foam, including PU, EVA, PE, CR, ECR, silicone foam, and so on. In the actual application process of the battery system, the foam suitable for the cell is generally PE, PU, and other materials; EVA, PE, ECR, EVA+CR, silicone foam, and other materials are generally used to support and absorb shock in the battery pack box. The foam used as a battery sealing ring is generally silicone foam and other materials.

The electric cell is the source of energy for electric vehicles, and the safety of the cell directly affects the safety of the whole vehicle. When the cell is working, it will generate a certain amount of heat, and thermal expansion and cold contraction will occur at different temperatures. The cell will bulge to a certain extent, and the long-term contact friction between the cell may lead to damage to the cell, resulting in battery failure and even being out of control.

The performance requirements of the new energy power battery for the foam products between the cell are as follows:

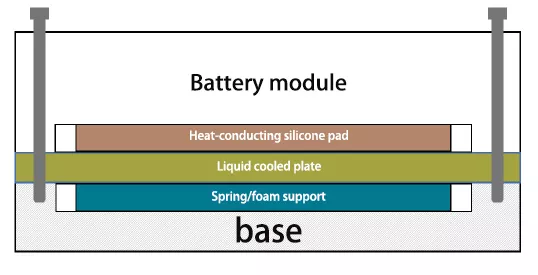

Thermal management plays an important role in power batteries, which is directly related to the safety of battery packs and vehicles. The cooling system inside the battery pack has been converted from a traditional air-cooled device to a liquid-cooled device. The heat-conducting silica gel is used to conduct heat between the battery pack and liquid-cooled plate, but due to the poor elasticity of heat-conducting silica gel, the thickness will be lost after long-term use. The contact between the liquid cooling plate and the battery string is insufficient, which affects the thermal conductivity.

A spring or foam can be set under the liquid cooling plate as a supporting material to ensure good contact between the liquid cooling plate, thermally conductive silicone, and the module.

The performance requirements of battery pack box support foam are as follows: